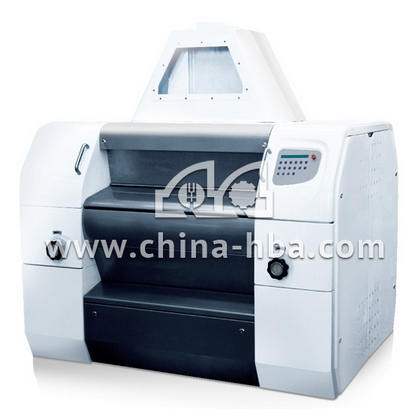

HMJR Frequency Control Roller Mill

• Turnover type feeding unit, convenient for the cleaning of feeding zone.

• Roller unit can be assembled and disassembled wholly from roller mill, convenient for practical operation, reducing down time.

• Frequency control feeding improves the feeding desire to the maximum, improving milling quality, saving power.

• Tooth wedge belt adopts elastic tightening device, compensating the belt’s minor deflection automatically, improving belt’s service life.

• Integral cast iron base renders higher stability.

• Parts in contact with stock adopt food grade 304 stainless steel.

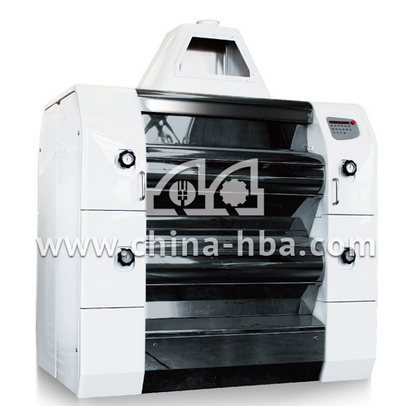

HMJR-8

• Two break systems or two reduction systems are immediately successive without intermediate sifting.

• It saves plansifter’ s area and pneumatic conveying costs.

• It saves equipment investment and floor area.

Technical specification

| Model | HMJR 25/125 | HMJR 25/100 | HMJR 25/80 | HMJR-8 25/125 | HMJR-8 25/100 | |

| Roller size (ΦxL) (mm) | 250×1250 | 250×1000 | 250×800 | 250×1250 | 250×1000 | |

| Feeding mode | Frequency control feeding | |||||

| Power / roller pair | Motor | Grade 6 | ||||

| Power (kw) | 7.5-30 | 5.5-22 | 5.5-15 | 7.5-30 | 5.5-22 | |

| Weight (kg) | 3800 | 3200 | 2700 | 6200 | 5500 | |

| Dimension (mm) | 2080×1400×1895 | 1830×1400×1895 | 1630×1400×1895 | 2060×1422×2285 | 1810×1422×2285 | |