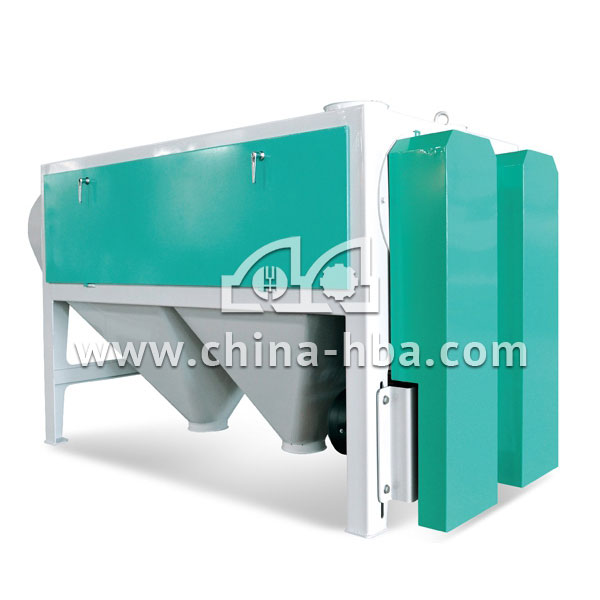

HDFD Bran Scourer

• Después de ser afectado por placas de batería de alta velocidad, Las piezas de salvado con harina se arrojan a placa de amortiguación y placa de tamiz de acero inoxidable perforado. Bajo el efecto de golpear las placas, La harina se separa del salvado, pasa por los poros de tamiz y cae en la tolva de descarga. Así se mejora la tasa de extracción de harina.

• El cuerpo adopta placas de acero de calidad principal, nivelado y suave.

• Rotor, El eje principal y las placas de paliza han pasado por la prueba de equilibrio dinámico integralmente, la carrera es más estable.

• La placa de tamiz de acero inoxidable puede mejorar enormemente la eficiencia de trabajo.

Especificación técnica

| Modelo | Diámetro del cuerpo de tamiz (milímetro) | Longitud del cuerpo de tamiz (milímetro) | Capacidad (t/h) | Energía (kilovatios) | Peso (kg) | Dimensión (milímetro) |

| HDFD30 | 300 | 800 | 0.9-1.1 | 2.2 | 360 | 1307× 436 × 1568 |

| HDFD 30 × 2 | 300 | 800 | 1.8-2.2 | 2.2×2 | 720 | 1307× 872 × 1568 |

| HDFD45 | 450 | 1100 | 1.3-1.6 | 4.0 | 400 | 1707× 568 × 1568 |

| HDFD 45 × 2 | 450 | 1100 | 2.6-3.2 | 4.0×2 | 800 | 1707× 1172 × 1568 |