منذ بداية القرن العشرين, بسبب متانتها, تم استخدام صوامع الصلب المختلفة على نطاق واسع في صناعة الحبوب. على الرغم من أنها هياكل فولاذية قوية, سوف تفقد قوتها وتتضرر في النهاية إذا تم استخدامها وصيانتها بشكل غير صحيح.

السبب الرئيسي لتدمير الصومعة الفولاذية هو الاستخدام غير السليم والصيانة غير السليمة. إن الفحص المنتظم للصوامع الفولاذية واستخدام تكنولوجيا الدخول والخروج الصحيحة يمكن أن يطيل عمر الخدمة لعدة سنوات.

تحتوي مخزن الحبوب الفولاذي على هيكل ذو قشرة رقيقة. للحفاظ على شكله وبنيته, its sidewalls must be evenly loaded. In view of the fact that the side walls and bottom of the steel silo carry loads of tons of stored grain, the silo foundation must be properly designed and maintained.

1Regular maintenance inspection

For regular maintenance and inspection of steel silo, the basic parts should be checked first.

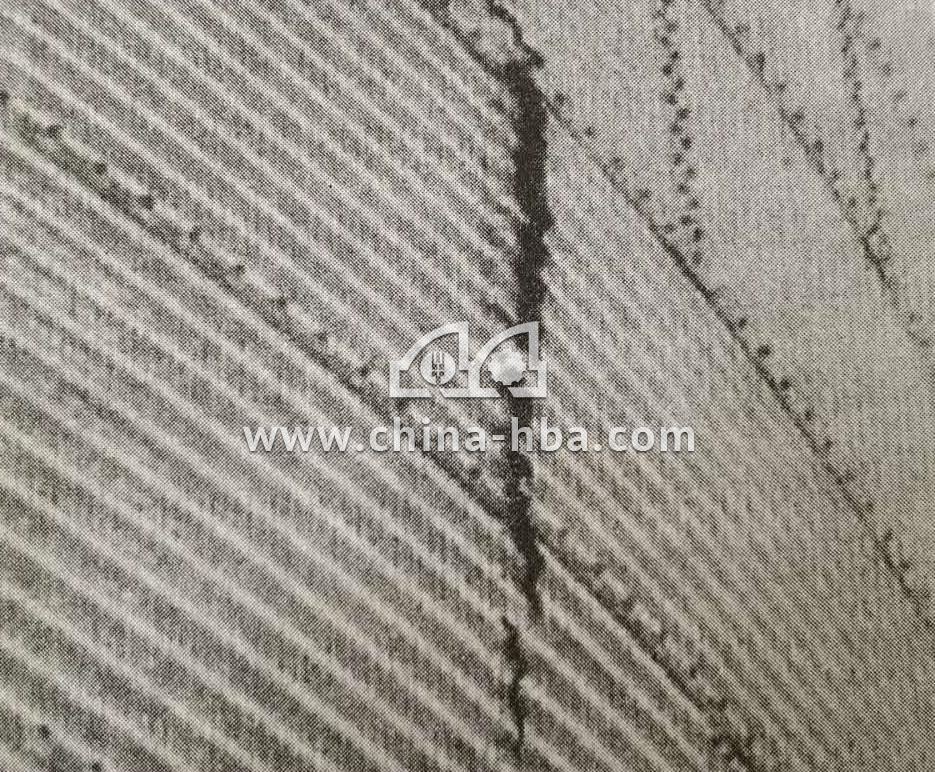

The foundation must be strong enough to support the stored grain load and prevent the empty silo from dumping or tearing by the wind. لذلك, the storage base must not show symptoms such as uneven settlement, large cracks (Figure 1), broken concrete, failure or looseness of anchor bolts. There should be a waterproof seal between the bottom surface of the warehouse body and the foundation.

Regular maintenance and inspection of steel silo should also include checking whether the silo body shows abnormal conditions such as stiffening bar bending, steel plate bulging, bolt looseness and overall abnormal shape. Sometimes it is even found that the warehouse body is tilted.

Figure 1 Such cracks in the steel silo foundation must reduce the steel silo to support grain storage Load capacity is easy to cause wind damage when the warehouse is empty.

If these symptoms occur, it must be determined whether the steel silo structure is strong. It should be pointed out that some steel plates, especially some steel plates in the middle of the warehouse body, show mild bulging, which is a normal working condition. لكن, excessive bulging is a sign that the corrugated steel sheet is about to be destroyed by abnormal wrinkles. (Figure 2)

Figure 2 The vertical cracks on the silo wall must be repaired immediately to avoid grain leakage.