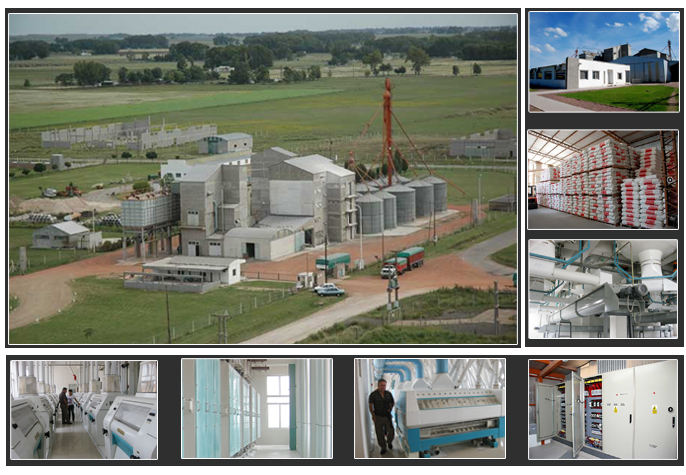

We’ve installed a 250T/D wheat processing complete set of equipment in Ireland of West Europe. Cleaning process adopts 1 sifting, two scourings, 1 de-stoning, 2 dampenings, 2 magnet separatings, two wheat blendings and three air suctions. Milling process adopts 4B7M2S2T6P2BrF technique. The project has 14 full automatic pneumatic roller mills, 6 plansifters, 4 purifiers, 10 impact detachers, 5 drum detachers, 1 scourer and 2 electronic packing scales. Whole production line adopts 6-storey building layout and full automatic PLC control. Enclosed pipeline is used for ventilation and de-dusting. This technical process is suitable for European, American and Canadian hard wheat with 0.5% ash content and below. Hihg automation saves human labor; the equipment layout is in good order and pleasing to the eye. The workshop has good hygiene conditions and production operations are flexible.